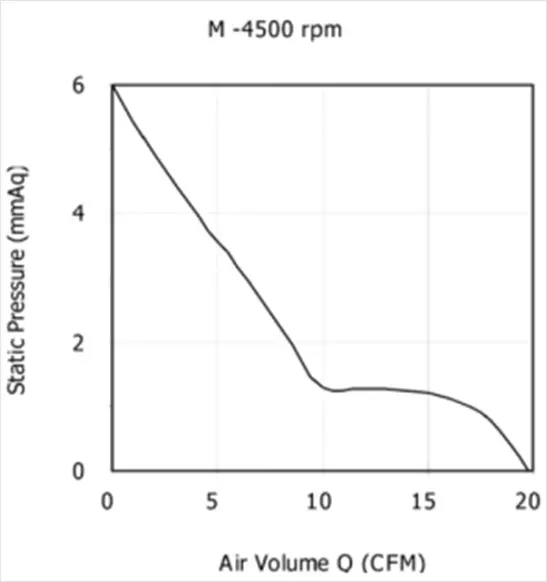

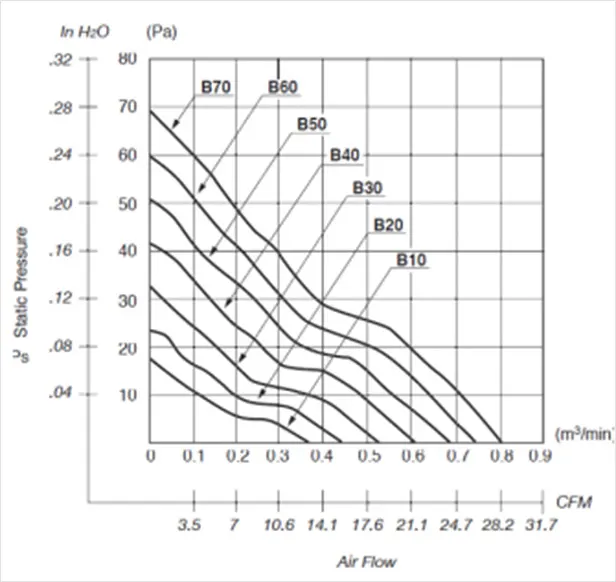

Forced air cooling is a heat dissipation method to realize the cooling of heat source parts by increasing the flow of air as a medium. By increasing the heat dissipation surface area of heat source and accelerating the air flow rate per unit time, good heat dissipation performance can be achieved quickly. Increasing the heat dissipation area can be achieved by installing heat sinks on the surface of the heat source. Generally, the heat sinks are fixed tightly on the heat source to achieve higher heat dissipation efficiency. To increase air flow, fans (fans) can be used to enhance ventilation and cooling effect. In most cases, the cooling efficiency can be greatly improved by adding heat sinks to the fan.

Forced air cooling is often used for cooling and heat dissipation of internal combustion engines. We can see that the external part of internal combustion engines on automobiles or motorcycles is not only designed as tooth flakes, but also equipped with a forced air-cooled exhaust hood, which is designed to increase the heat dissipation area, while the fan in the exhaust hood is used to enhance the air flow on the surface of internal combustion engines. Fast cooling of engine to ensure normal operation.

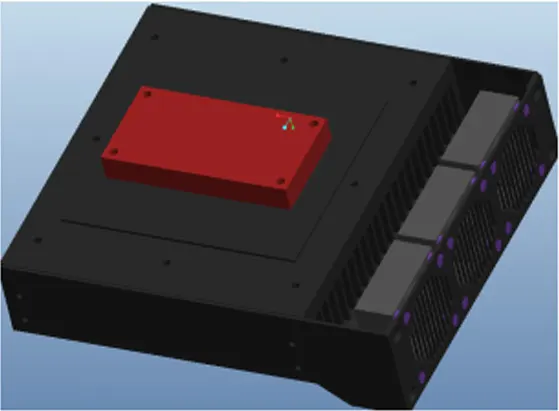

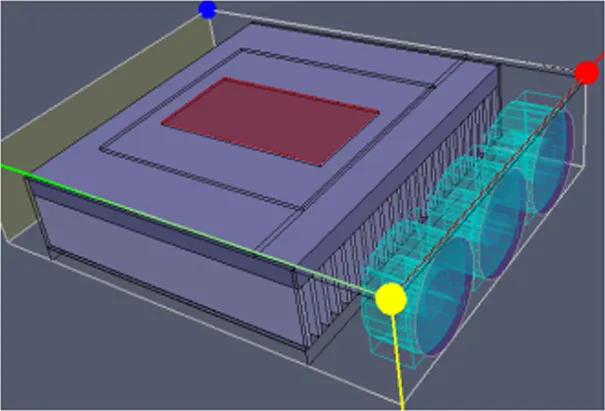

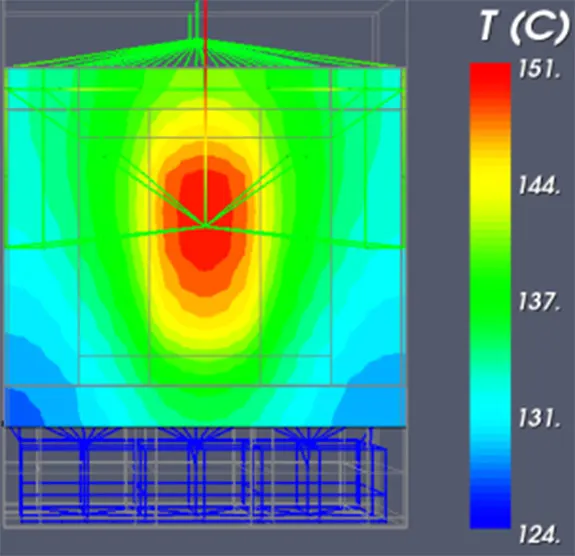

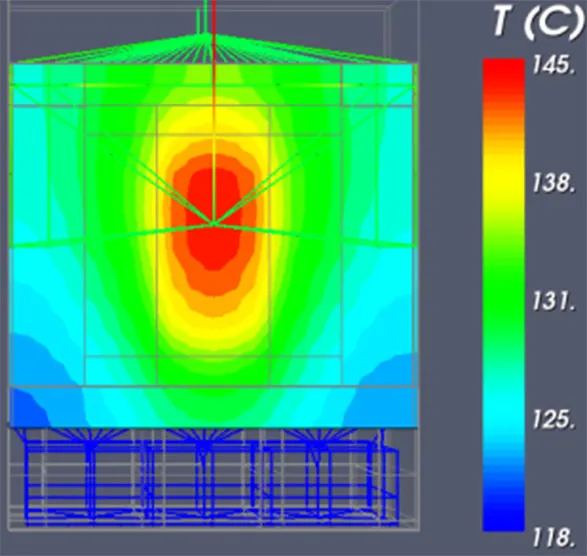

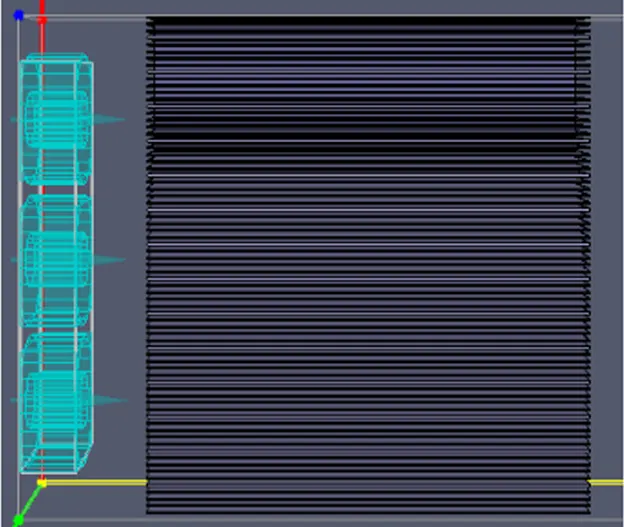

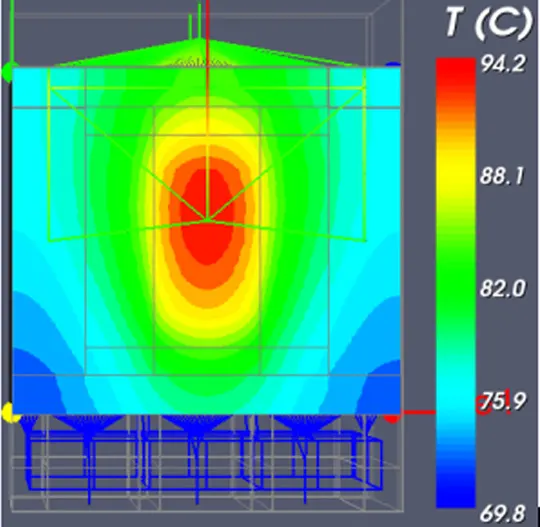

In recent years, Tongyu thermal energy has strengthened the research and development of forced air cooling technology, and realized the application of forced air cooling to heat dissipation of wind power converters, photovoltaic inverters, SVG and other high-power machines. The heat dissipation efficiency can be greatly improved by using the heat dissipation mode of high-power spade radiator + fan or high-power spade radiator + heat pipe.

Current Location:

Current Location: