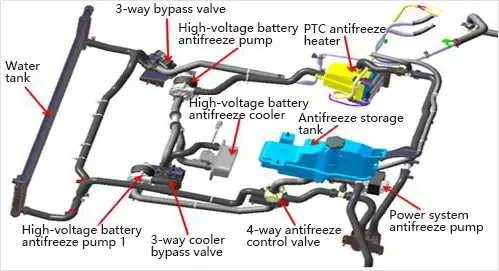

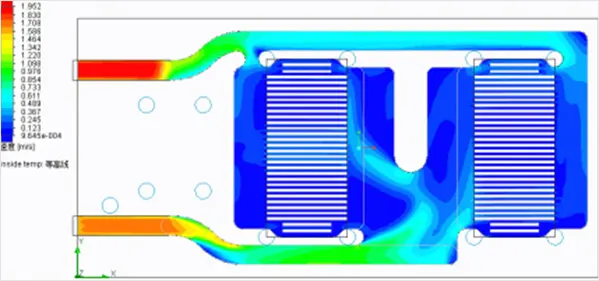

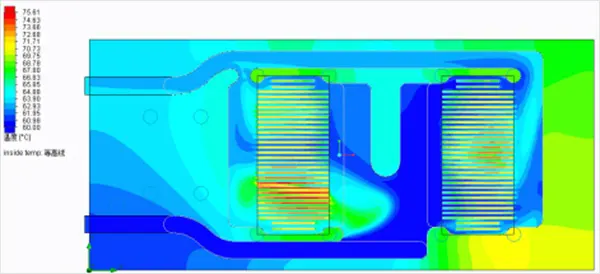

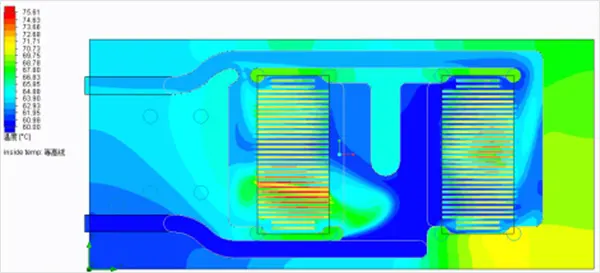

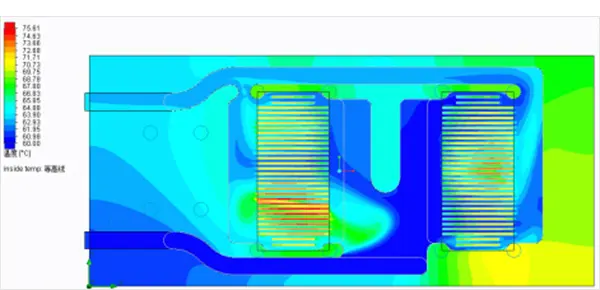

Liquid cooling technology is cooling technology of using the liquid flow to take heat away rapidly. Liquid-cooling application refers to the use of liquid-cooling cooling plates (also known as water-cooling cooling plates and liquid-cooling radiators) installed at the heat source, together with heat exchangers and heat exchange pumps, to dissipate heat by circulating liquid flow. Generally, liquid cooling technology is applied in the environment where forced convection or phase change system cannot achieve the heat dissipation effect and the heat energy density is extremely high.

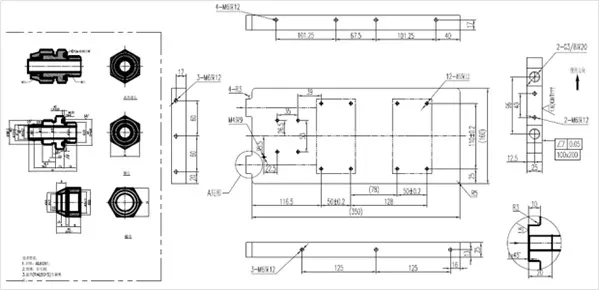

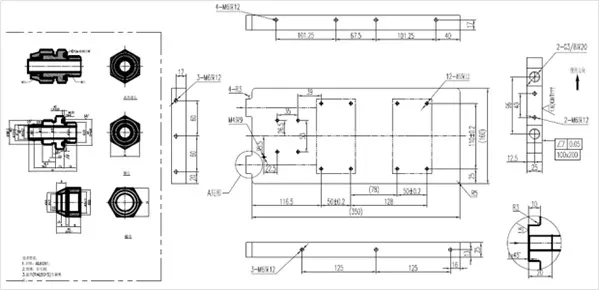

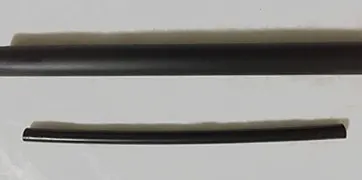

Tongyu Thermal increases the liquid cooling technology constantly in R&D, especially in the water-cooled product production process innovation. We obtained a number of technical patents in the copper pipe automatic bending, extrusion die, pressure pipe, adhesion welding and other technical processes, made the water-cooled plate welding more stable, greatly reduces the water-cooled plate leakage and other bad phenomena, and improved the reliability of water-cooled plate heat dissipation. Through the technical treatment of the surface of the liquid cooling plate,we can realize the contact with the heat source better and improve the efficiency of heat dissipation.