3C product also calls information home appliance, it is to show computer kind communication kind and consumer kind electronic product commonly. Various kinds of market demand are large. China has become the largest consumer market in the world for 3C products. With the improvement of national economic level and income level, Chinese has put forward higher requirements for the quality of electronic products. Businesses have launched products with higher configuration, higher performance and better design to satisfy consumers.

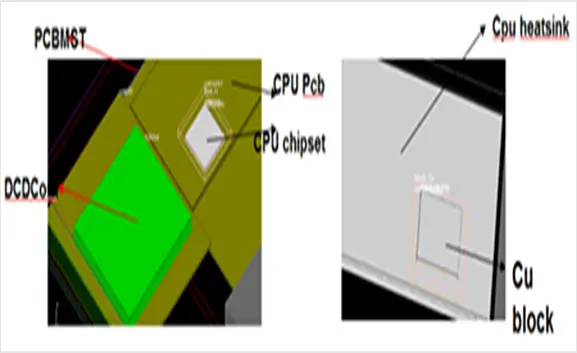

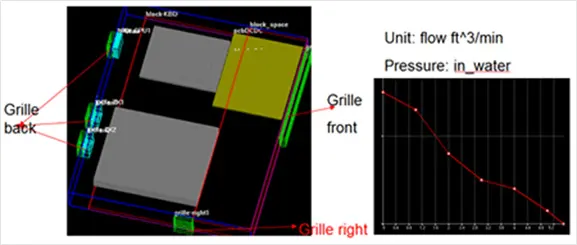

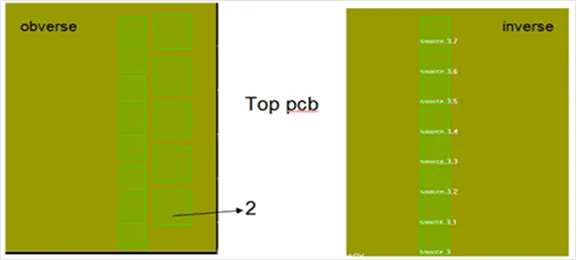

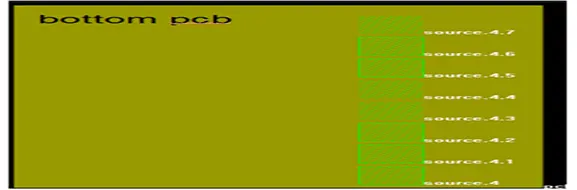

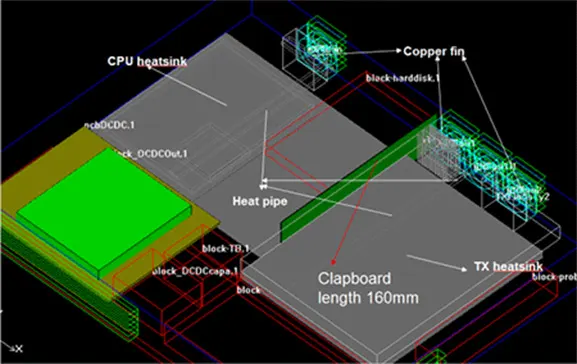

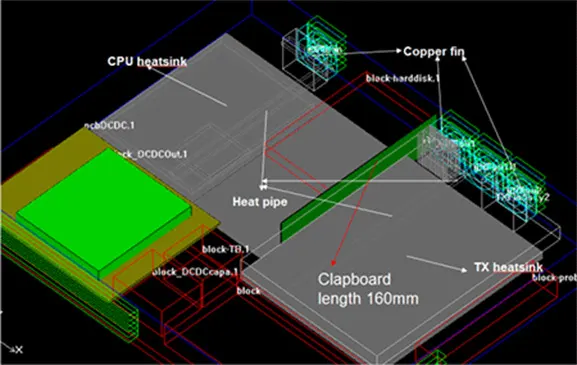

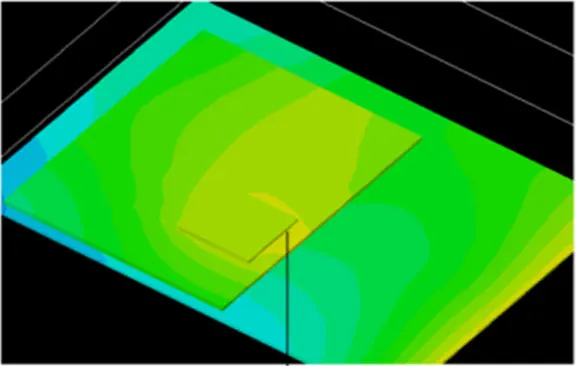

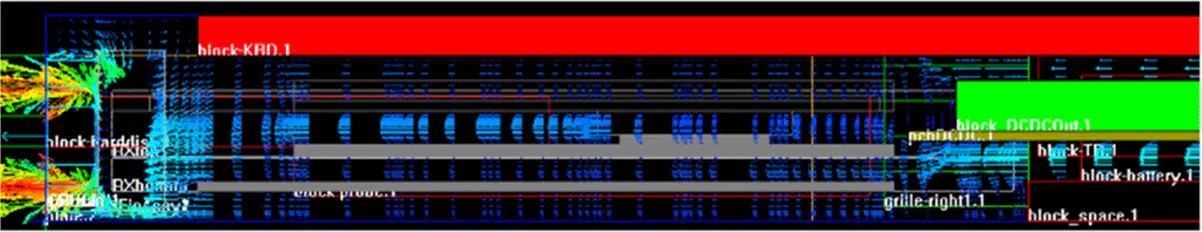

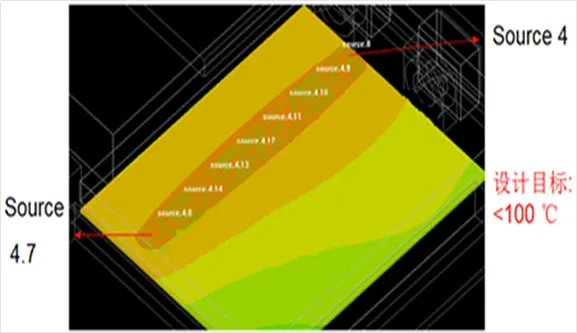

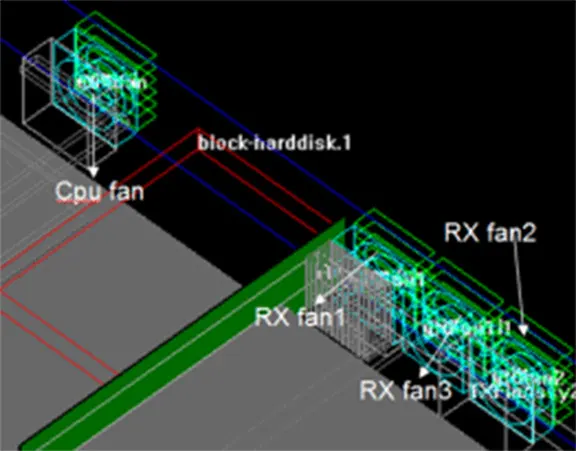

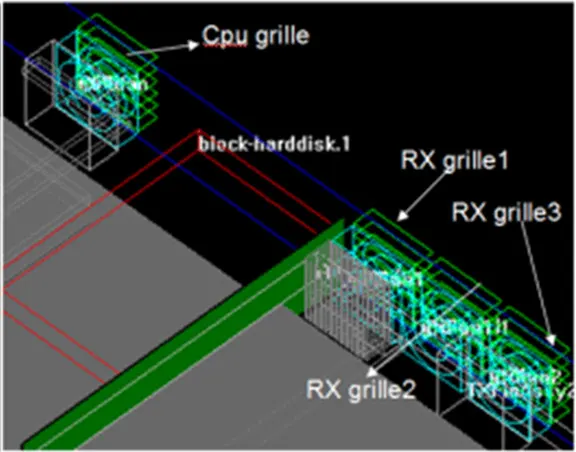

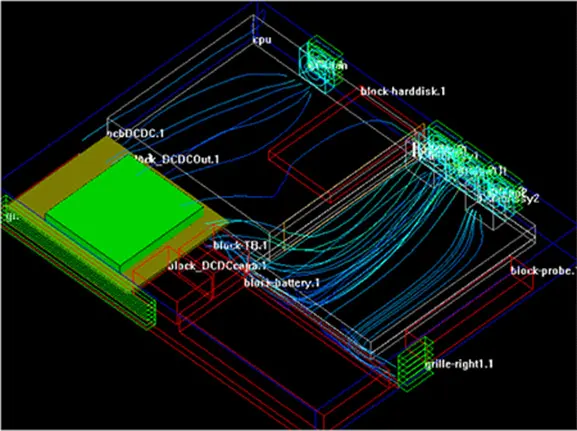

There are many factors affecting the quality of electronic products, among which heat dissipation is a non-negligible factor. Especially after the "samsung battery gate" incident in 2016, electronic manufacturers pay more attention to the heat dissipation performance and safety of products. How to ensure that the heat dissipation of electronic products in line with the stringent design requirements? Planning thermal management issues at the beginning of the product design cycle is the best way to achieve the most efficient cooling solutions. As the first-class heat dissipation technology service provider in China, TONGYU Thermal can provide IT communication electronic products cooling solutions, involving: board (motherboard) cooling, CPU cooling, graphics card cooling, radio frequency module cooling, RU cooling, game console cooling, VR cooling, industrial control computer (machine) cooling, server cooling, central variable frequency air conditioning cooling, TEC cooling and other fields.

There are many factors affecting the quality of electronic products, among which heat dissipation is a non-negligible factor. Especially after the "samsung battery gate" incident in 2016, electronic manufacturers pay more attention to the heat dissipation performance and safety of products. How to ensure that the heat dissipation of electronic products in line with the stringent design requirements? Planning thermal management issues at the beginning of the product design cycle is the best way to achieve the most efficient cooling solutions. As the first-class heat dissipation technology service provider in China, TONGYU Thermal can provide IT communication electronic products cooling solutions, involving: board (motherboard) cooling, CPU cooling, graphics card cooling, radio frequency module cooling, RU cooling, game console cooling, VR cooling, industrial control computer (machine) cooling, server cooling, central variable frequency air conditioning cooling, TEC cooling and other fields.

Current Location:

Current Location: