Power batteries are the batteries that provide power for machines as power sources, generally referring to the batteries that provide power for new energy vehicles such as electric vehicles, electric trains and so on. New energy vehicles refer to those vehicles with advanced technology in power control and drive, which are formed by using unconventional vehicle fuel as power source and integrating advanced technology in vehicle power control and drive. New energy vehicles are regarded as promising because of their energy-saving and environmental protection characteristics and are strongly supported by national policies to implement the State Council's policy on fostering strategic emerging products. Deployment and requirements for energy conservation and emission reduction should be strengthened. The central government should allocate special funds to support the pilot project of subsidies for private purchases of new energy vehicles.

New energy vehicles are mainly composed of battery drive system, motor system, electronic control system and assembly. Among them, motor, electronic control and assembly are basically the same as traditional automobiles. The biggest difference lies in the difference of power sources. Power battery pack is an important power source for new energy automobiles. The majority of new energy automobile enterprises have increased their research and development on power battery pack to solve the technical bottleneck of high cost, weak battery endurance and low charging speed of power battery pack. In addition, technical cooperation with heat dissipation enterprises such as thermal energy is launched to improve the performance of power battery packs.

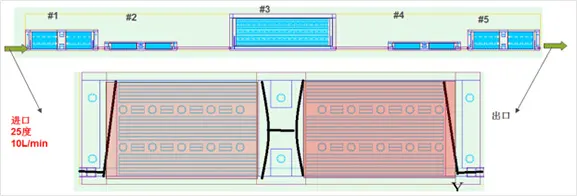

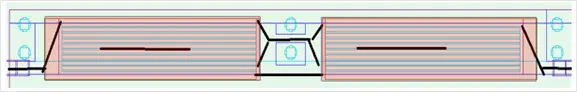

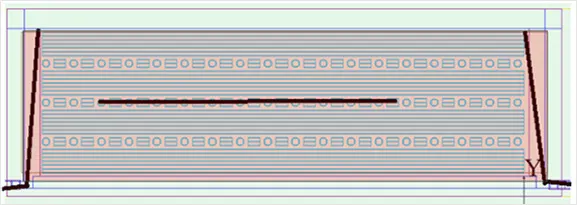

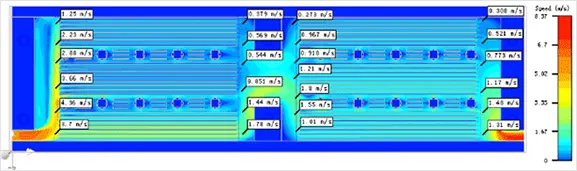

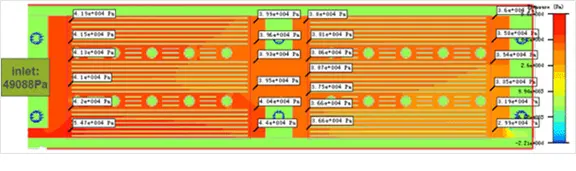

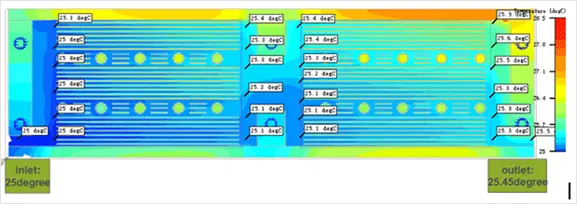

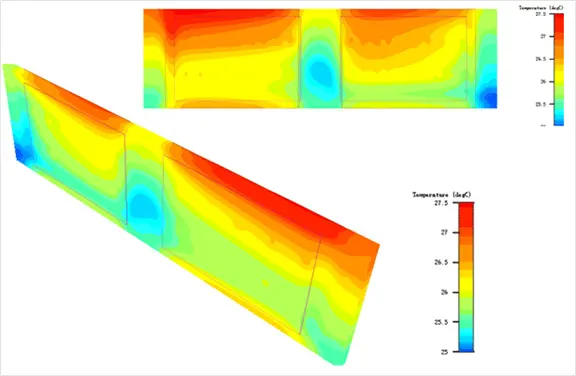

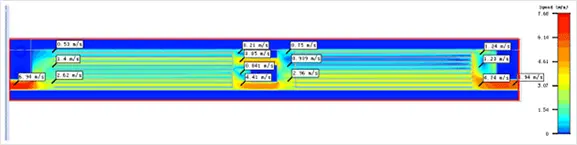

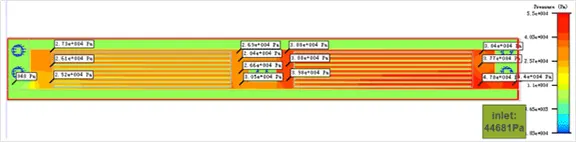

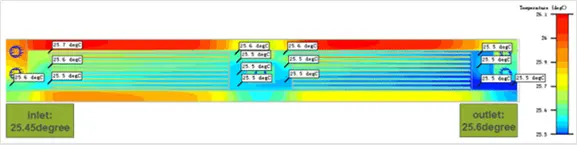

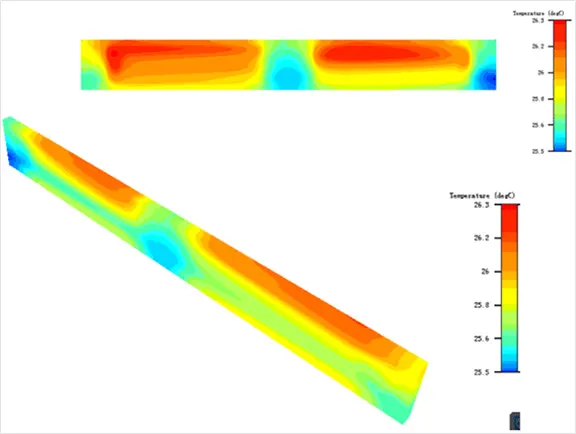

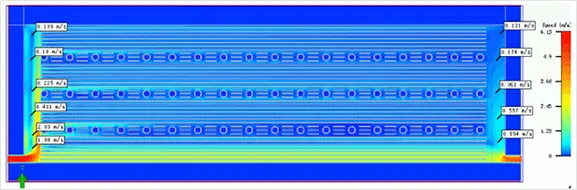

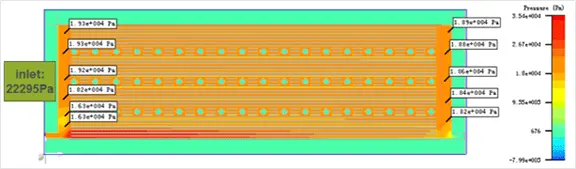

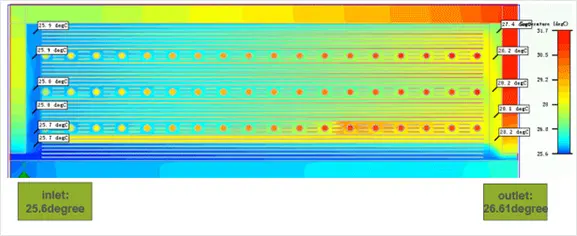

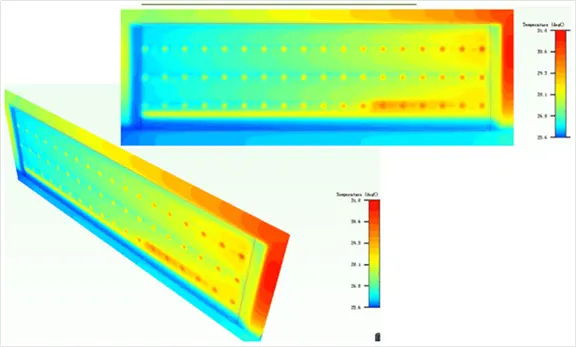

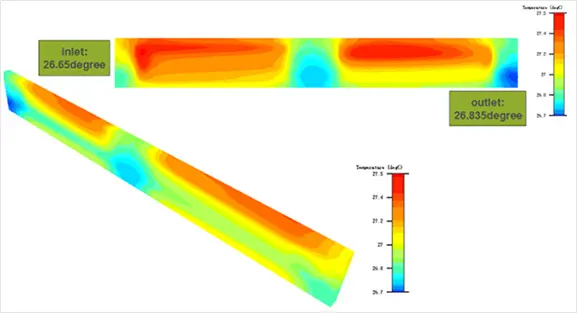

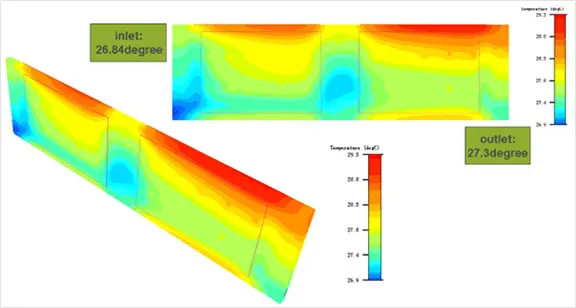

Tongyu Thermal Energy is committed to becoming a leader in heat management in the field of new energy. It has rich experience in the research and development of heat dissipation technology for power battery packs. Through in-depth discussions between Tongyu thermal design engineers and automotive technicians, Tongyu Thermal Energy helps new energy automotive enterprises to solve heat dissipation problems, which has been widely praised by the industry. Following is a demonstration of the heat dissipation schemes for power battery packs developed and produced by YueHE. More new water-cooled heat dissipation schemes have not been demonstrated due to the confidentiality of confidentiality protocols and preventive technologies. They can communicate with customer service or come to direct technical exchanges with YueHE.

New energy vehicles are mainly composed of battery drive system, motor system, electronic control system and assembly. Among them, motor, electronic control and assembly are basically the same as traditional automobiles. The biggest difference lies in the difference of power sources. Power battery pack is an important power source for new energy automobiles. The majority of new energy automobile enterprises have increased their research and development on power battery pack to solve the technical bottleneck of high cost, weak battery endurance and low charging speed of power battery pack. In addition, technical cooperation with heat dissipation enterprises such as thermal energy is launched to improve the performance of power battery packs.

Tongyu Thermal Energy is committed to becoming a leader in heat management in the field of new energy. It has rich experience in the research and development of heat dissipation technology for power battery packs. Through in-depth discussions between Tongyu thermal design engineers and automotive technicians, Tongyu Thermal Energy helps new energy automotive enterprises to solve heat dissipation problems, which has been widely praised by the industry. Following is a demonstration of the heat dissipation schemes for power battery packs developed and produced by YueHE. More new water-cooled heat dissipation schemes have not been demonstrated due to the confidentiality of confidentiality protocols and preventive technologies. They can communicate with customer service or come to direct technical exchanges with YueHE.

Current Location:

Current Location: