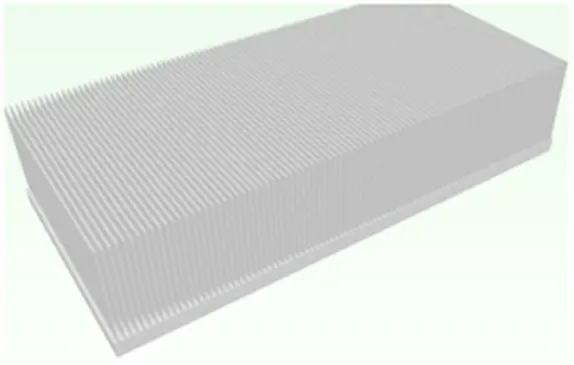

The wind power converter uses the rotor of the doubly-fed asynchronous wind generator to excite, which makes the amplitude, frequency and phase of the stator side output voltage of the doubly-fed generator the same as the power grid, and the active and reactive power can be independently decoupled as required. The converter controls the doubly-fed asynchronous wind generator to realize soft grid-connection and reduce the adverse impact of grid-connection and motor from electric current. It can be said that whether the wind power converter runs stably directly affects the stability of the power grid. How to ensure the normal operation of wind power converter, heat dissipation is an indispensable step.

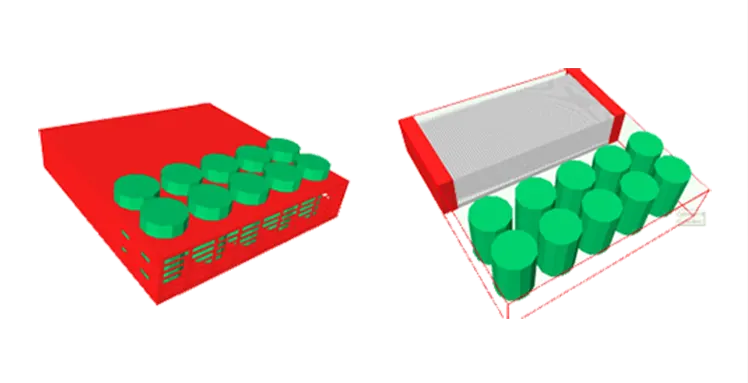

TONGYU THERMAL is rooted in the R&D of heat dissipation in the new energy field. In the field of wind power converter, we make strategic cooperation with wind power converter manufacturers in domestic and foreign, providing reliable wind power converter, inverter, motor and other cooling technology support. Tongyu met the service requirements from thermal design, thermal simulation to the production integration and integrity, widely praised by wind power manufacturers.

TONGYU THERMAL is rooted in the R&D of heat dissipation in the new energy field. In the field of wind power converter, we make strategic cooperation with wind power converter manufacturers in domestic and foreign, providing reliable wind power converter, inverter, motor and other cooling technology support. Tongyu met the service requirements from thermal design, thermal simulation to the production integration and integrity, widely praised by wind power manufacturers.

Current Location:

Current Location: