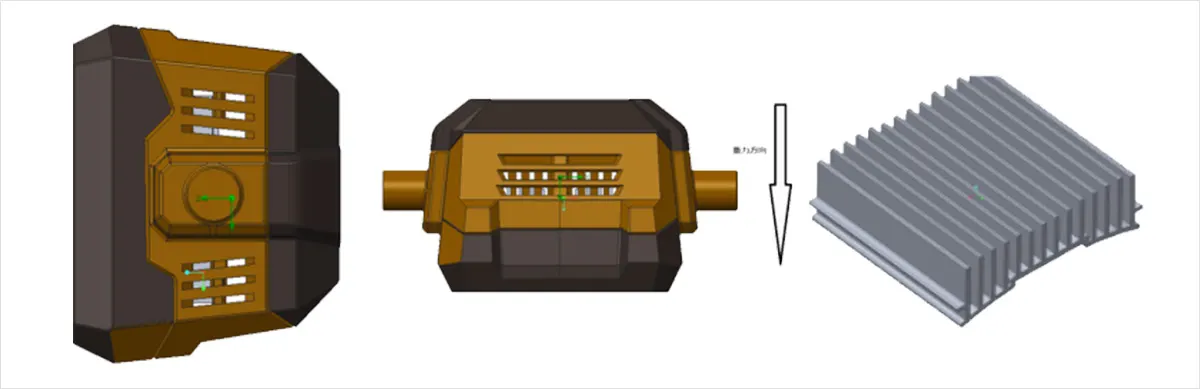

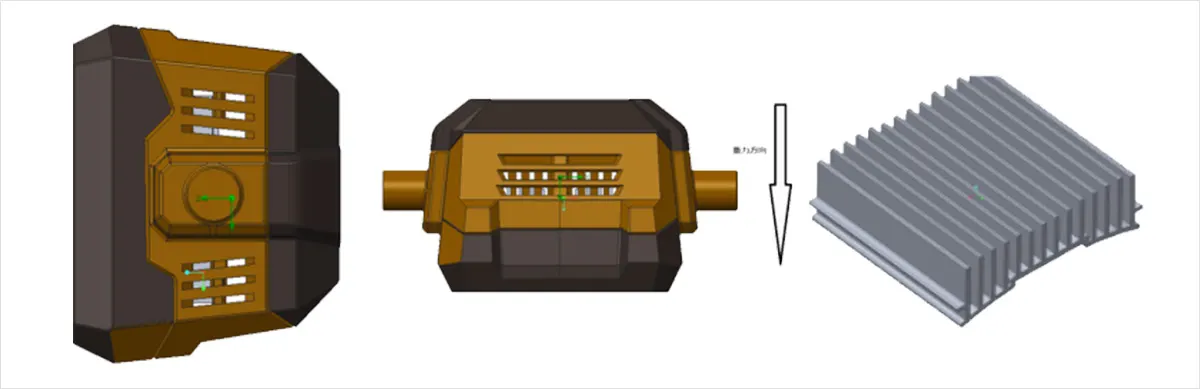

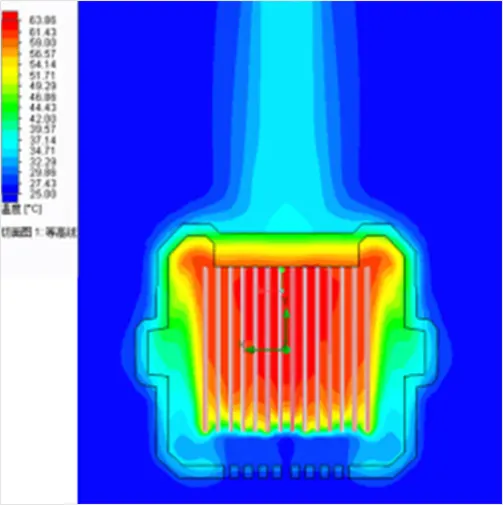

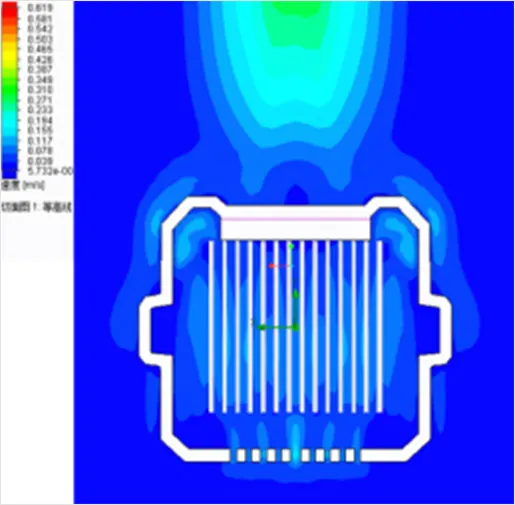

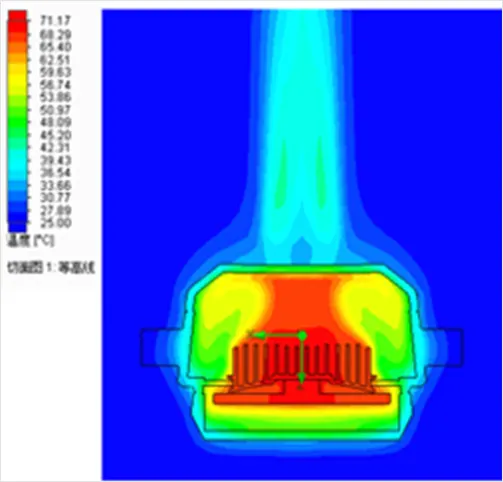

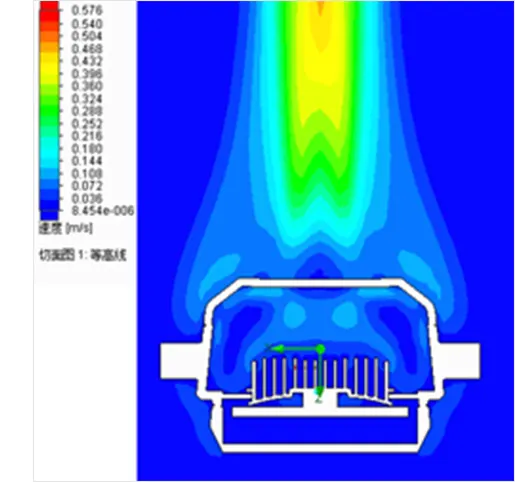

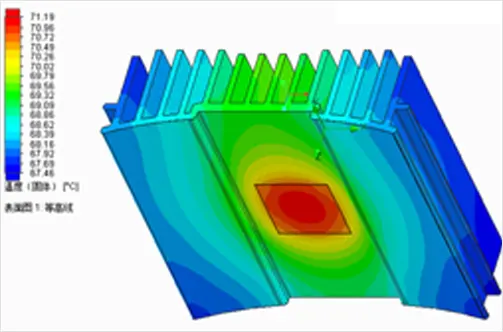

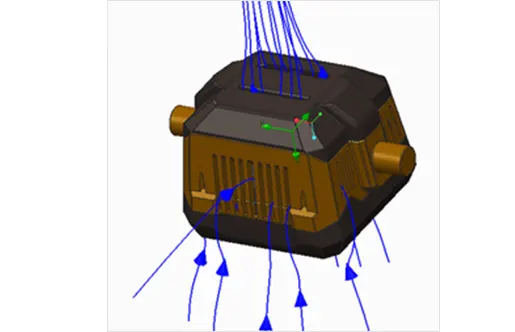

Natural cooling is the most commonly used cooling method. Natural cooling is a cooling method that USES the high thermal conductivity of materials (mainly refers to profiles) to remove heat and send heat into the air. That is, in the absence of specific wind speed requirements, the use of natural convection fin is copper aluminum heat dissipation plate, heat dissipation aluminum extrusion parts, heat dissipation machine processing or heat dissipation alloy casting to achieve heat dissipation products.

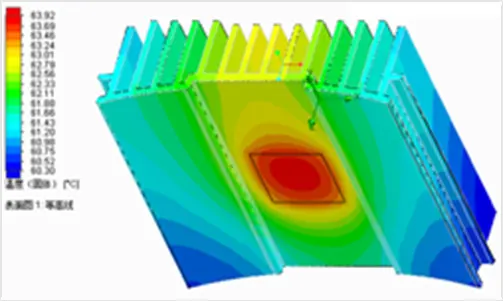

Tongyu Thermal focuses on high-power heat dissipation and has made breakthroughs in the research and development of natural cooling technology in recent years. For example: the independent development of high density blade cutting technology, ultra-thin fin, ultra-small spacing, ultra-high multiple radiator main structure of the production, can be a comprehensive replacement for insert heat dissipation technology, with a larger heat dissipation area, one-time molding, 100% profile thermal conductivity, higher heat dissipation performance of the advantages; In profile radiator process innovation, the use of the most advanced friction welding technology, to solve the profile can not meet the needs of ultra-wide body heat dissipation technology bottleneck, smooth realization of greater heat dissipation power, greater heat dissipation structure breakthrough; And so on.

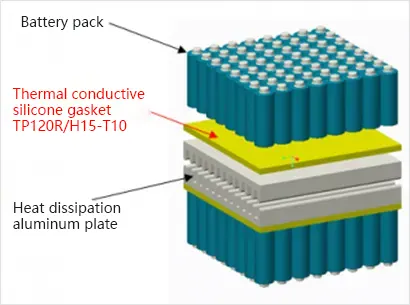

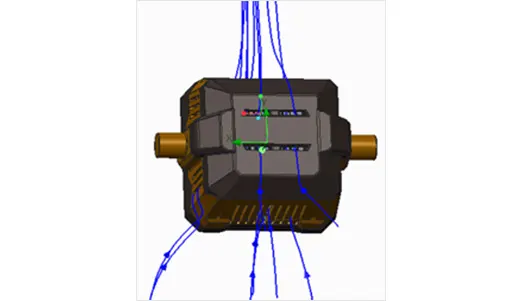

Technological innovation is the cornerstone of TONGYU Thermal energy's long-term development. Through the in-depth study of natural cooling technology, the realization of higher heat efficiency, at the same time, using new technology to provide clients with better optimized cooling solutions, won the praise of customers in many industries, with abundant of natural cooling by heat radiator is widely used in: uninterruptible power supply (UPS) heat dissipation, special power supply high voltage inverter in cooling, heat, solar energy storage heat dissipation, power battery cooling, rail transportation motor cooling, etc.